Backed by Hugging Face founder Clement Delangue and early Uber and Twitter investor Naval Ravikant, San Francisco-based MicroFactory has closed a $1.5 million pre-seed round, giving the company a $30 million post-money cap as it pushes to redefine automation in manufacturing.

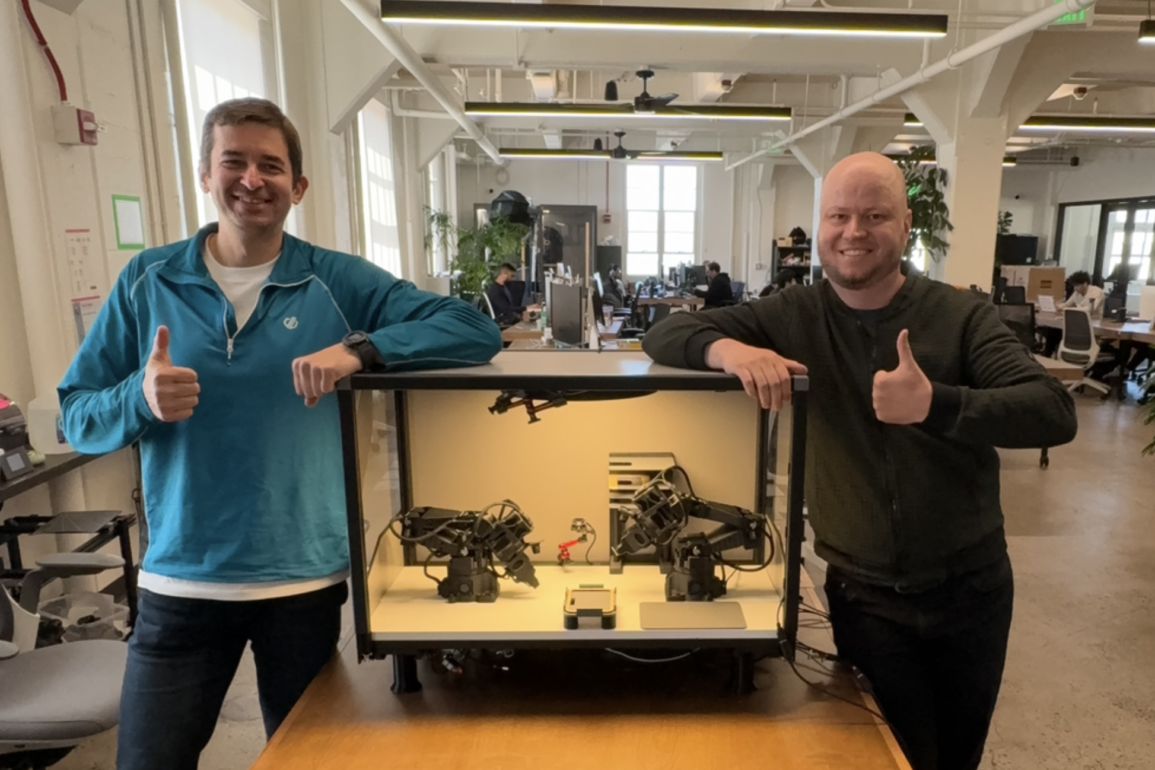

At the heart of MicroFactory’s vision is an AI-powered, general-purpose robotic system: a compact, box-shaped unit with two robotic arms and interchangeable tools, designed to sit on a desktop and priced at just $5,000.

Already, more than 100 customers across industries such as electronics, textiles, food processing, jewelry, and laboratory work have placed paid reservations, with the first commercial units slated for delivery in early 2026.

Unlike humanoid robots, MicroFactory’s machine is deliberately simple—ten times cheaper and easier to manufacture, with no legs, no batteries, and no fragile human-like fingers. Its enclosed box design stabilizes lighting and camera positioning, making training more efficient, data more transferable, and operation safer for both workplaces and homes.

MicroFactory_Demo Video – assembly (fast speed)

“You don’t need a humanoid robot to automate tabletop work,” said Igor Kulakov, co-founder and CEO of MicroFactory. “Our robot design allows us to automate tasks with the current state of robotic AI models and hardware. To prove it we created a demo of assembling a real product for our client, which had previously been assembled by an offshore factory. This design also helps the robot to be affordable and safe.”

The robot learns tasks through demonstration rather than complex coding, performing precision work like soldering, screwing, cable routing, peeling plastic layers, and light-duty food processing. MicroFactory began with electronics assembly for a reason: the robot can even build other robots, a self-reinforcing approach that paves the way for fully automated production lines in the U.S. By targeting small and mid-sized businesses, the company aims to generate a growing pool of training data that accelerates deployment and makes its robots smarter over time.

Looking ahead, MicroFactory is setting its sights on deploying 100 million robots worldwide, automating vast swathes of manual labor and driving the cost of hardware below $1,000 per unit. With its early momentum, bold design, and high-profile backers, the company is positioning itself not just to build robots, but to reimagine the economics of global manufacturing.